- Updated On: August 06, 2025

Solar Panel Recycling: What to Do with Panels After Their Lifespan?

Renewable energy is a source of sustainability, but it raises a new question: “What to do with solar panels after 25 years of their usable life? Solar panel recycling matters to the energy sector as they address the financial and environmental implications of disposing of old solar panels. As more solar installations are growing, a huge number of solar panels will eventually be nearing the end of their useful life and become waste. Recycling the panels allows for the recovery of valuable resources while not allowing pollutants to landfills to make their way into our environment.

We will explore how to recycle solar modules and the different methods for solar recycling in this article.

Why is solar panel recycling important?

Recycling solar panels is an opportunity to procure valuable raw materials and save the groundwater from leaching toxic materials through landfills. According to the International Renewable Energy Agency, we can get about $450 million worth of raw material from old panels globally at the end of 2030. This amount is equivalent to the cost of materials to manufacture at least 60 million new solar panels. It reflects that recycling panels is profitable not only for the planet but also for the economy. Also, in the case of no recycling, 60 million tons of PV panel waste will impact landfills by the year 2050. This is because all PV cells contain a certain number of toxic substances, which would truly become a un-sustainable way of sourcing energy.

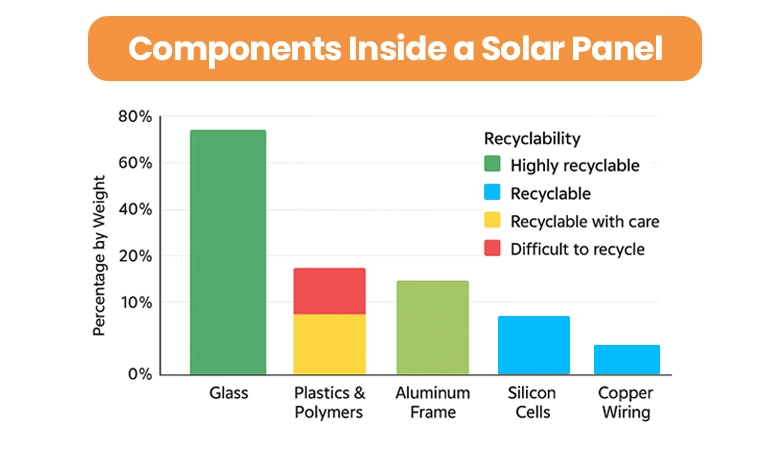

What parts of solar panels are recyclable?

Metals, glass, copper, and silver wires are completely recyclable. However, silicon cells, the main component of solar PV modules, are not quite recyclable. Some companies have the technology to reutilize silicon cells in their original form. While other companies melt silicon cells and extract silicon out of the solar cells. Later on, the manufacturing of new solar panels using this silicon takes place. Thus, jacking up the price of solar recycling.

To curtail the cost of solar recycling, scientists separate silicon cells from EVA using a dibasic ester. No harmful by-product formation takes place during this purpose. That is the main reason why this technique is gaining traction in the recycling solar panels industry. This proves that with the right technique, everything can be recyclable.

What is the process of recycling solar modules?

Two primary categories of solar panels require distinct recycling strategies. Thin-film and silicon solar types can both recycle through different industrial methods. Several solar technologies have been developed as a result of research on solar panel recycling. Although some even achieve an incredible 96% recycling efficiency, the goal is to set better standards in the future. Advanced robotics and artificial intelligence are also simplifying the sorting and disassembly procedures, increasing recycling’s effectiveness.

Silicon-Based Solar Panel Recycling

The first step in recycling silicon-based photovoltaic panels is separating the solar panel to remove the glass and aluminum components. To separate the aluminum and glass components, silicon PV panels must first require dissembling. The majority of the glass (95%) is reusable, while the metal components on the exterior can re-mold cell frames. In a thermal processing unit, the other substances are heated to 500°C to facilitate the binding of the cell components. The plastic covering gets evaporated because of the high temperatures and becomes available for further processing as silicon cells. Not a single piece of this plastic is a waste because of the underlying technologies. Therefore, reused as a heat source for further thermal processing.

During the thermal process, the hardware detaches. 80% of the material is ready for reuse while the remaining is then go through the refining process. To etch away silicon wafers, acid is used. Through this process, 85% recycling rate is achievable. By melting broken wafers, new silicon modules produces.

Thin-Film-Based Solar Panel Recycling

Thin-film panels go through more intensive processing. They put them through a shredder initially. Then, a hammermill ensures no particle size is larger than 4-5 mm, whereupon the lamination uniting the internal parts dissolves and removed. The remaining material is made up of both liquid and solid components, in contrast to silicon-based PV panels. While the liquid drips into a container, the solid components continue to rotate inside a tube, separated by a revolving screw.

To guarantee purity, liquids undergo a precipitation and dewatering procedure. To fully separate the semiconductor ingredients, the resultant material undergoes metal processing. 95% of the semiconductor material is reused on average, but the last step varies depending on technology to produce the panels. Such so-called interlayer materials, which are less dense and stripped away by a vibrating surface, pollute solid matter. Then the material is cleaned. 90% of the glass material retains for simple remanufacturing and only pure glass remains.

What are the future benefits of solar waste management?

In order to handle the massive amounts of PV modules set to waste in the near future, the need is for an effective infrastructure for recycling solar panels. With recycling by 2050, the PV market will contribute more than $11 billion in recoverable value and other green job creation.

Without spending money on raw materials, this infusion will enable the production of 2 billion additional panels. This indicates that repurposing used materials will have the potential to generate about 630 GW of electricity. As the solar installation trend is booming, there will be more economic opportunities in the solar cell recycling sector.

Summarizing, recycling solar panels is the key to minimizing environmental footprint while preserving precious resources. There is an absolute reduction in landfill waste via the reuse of metals, glass, and silicon, thus moving further towards sustainable renewal energy development. Efficient recycling practices will make solar energy an uncompromisingly green solution for the future.

If you have not yet installed solar panels and are looking for a reliable solar installer in your vicinity, Solar SME offers affordable solar and backup solutions. You may get a FREE Quote for estimation.

Related Articles:

Solar power is not just the cleanest; it’s the most abundant energy source on our planet. It’s estimated that the entire United States could be powered with about 22,000 square miles of solar panels.

Solar energy is an eco-friendly substitute for fossil fuels, which release greenhouse gasses that cause climate change. Solar energy is growing in popularity.

There are many ways to save with solar, including a 30% extended tax credit. The environmental benefits are the second most popular reason. Most of the power produced in the United States comes from the burning of fossil fuels such as coal and natural gas. In contrast, solar panels generate clean, renewable, and emission-free electricity. Explore the benefits of clean solar power and top reasons to invest!