The solar panels industry has once again led the way in America’s energy transformation. According to the report by Wood Mackenzie, Global Solar Module Manufacturer Rankings, the top 10 solar panel manufacturers shipped a combined 500 gigawatts (GW) of photovoltaic (PV) modules. That is almost double the volume shipped in 2023. Despite the huge growth in solar panel installations, the top companies still reported losses of $4 billion. Falling prices, rising competition, and high production costs made it tough to stay profitable.

Industry Focused on Survival Through Scale

Yana Hryshko, Head of Global Solar Supply Chain at Wood Mackenzie, has explained the challenge. “2024 was a year of survival through scale,” she said. Even with lower earnings, they pushed forward, investing more in making the most efficient solar panels and keeping on maintaining their market share. This long-term strategy may give results, especially as more people ask, How do solar panels work?, and consider switching to home solar panels. But high prices and rising production costs added pressure. Moreover, top solar companies invested more in new tech. The main aim is to lead the solar industry in the long run.

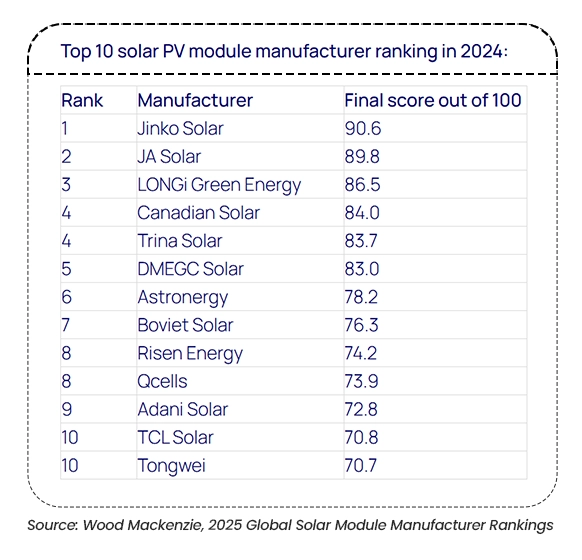

Global Ranking Shows Shifting Market Dynamics

JinkoSolar remains one of the world’s largest module manufacturers, with projected shipments surpassing 43 GW in 2025. Right behind is JA Solar, aiming for around 45 GW, while LONGi Green Energy looks set to deliver between 38 and 40 GW. Other major players like Canadian Solar, Trina Solar, and Adani Solar also made the top 10 list. These rankings looked at several things how much each company can produce, how advanced their technology is, and how solid their supply chains are.

Geographic Expansion Eases Trade Tensions

Top solar panel makers are now expanding their factories across the solar world. In fact, 7 out of the top 10 are building in at least three different countries. Places like India, Vietnam, and Mexico are becoming new areas for solar panel production. Furthermore, companies plan to broaden into Egypt, Saudi Arabia, and South Africa. This helps lower the cost of solar panels. The shift in manufacturing also brings the benefits of solar panels closer to new regions. It allows companies to deliver solar panels for home use at a faster pace and more competitive price.

Vertical Integration Gains Momentum

Many solar companies are now trying to control every step of production. Companies are now making their own wafers and cells, not just panels. This gives them more control over quality and helps them respond faster to supply chain problems. This strategy is especially helpful as more people explore solar panels on roof for homes and businesses. Having full control over production ensures quicker delivery, gives better control over cost, and creates more durable systems.

N-Type Solar Panels Become Mainstream

A big shift in solar panel technology is N-type solar panels. In 2024, most top brands focused on N-type solar panels. Jinko Solar reported that 87% of its modules were N-type. TOPCon technology led the way, with over 24% energy conversions. Meanwhile, other new technologies like HJT and back contact panels are also getting dominant. Manufacturers are now investing in these solar solutions to stay competitive, as they offer better results, key traits people look for when they buy solar panels

To sum up, the solar industry is growing quickly with better technology. Now is a great time to choose solar panels installation for a cleaner and more affordable energy solution.

News Source: Wood Mackenzie Magazine